Meet the xBeam 3D Metal Printing

Exclusive for R&D, friendly for industry!

NVO Chervona Hvilya presents

xBeam 3D Metal Printing –

the metal Additive Manufacturing technology which was born to make 3D printing of metals available for the widest industrial community.

xBeam 3D Metal Printing allows you to quickly and efficiently produce high-quality metal products of any size from ordinary wire.

xBeam 3D Metal Printing provides a numerous exclusive technological possibilities in R&D opening new opportunities in topology optimization, application of new materials in 3D printing, development of new compositions, as well.

xBeam 3D Metal Printing –

the metal Additive Manufacturing technology which was born to make 3D printing of metals available for the widest industrial community.

xBeam 3D Metal Printing allows you to quickly and efficiently produce high-quality metal products of any size from ordinary wire.

xBeam 3D Metal Printing provides a numerous exclusive technological possibilities in R&D opening new opportunities in topology optimization, application of new materials in 3D printing, development of new compositions, as well.

Core Technology

xBeam 3D Metal Printing

allows no longer have to choose between fine accuracy, defect-free metal structure and high productivity.

The new patented solutions are based on the exclusive ability of gas-discharge electron beam gun to generate hollow conical electron beam providing unique physical conditions for precisely controllable metal deposition and forming of desired metal structure in produced 3D metal part.

Read more

allows no longer have to choose between fine accuracy, defect-free metal structure and high productivity.

The new patented solutions are based on the exclusive ability of gas-discharge electron beam gun to generate hollow conical electron beam providing unique physical conditions for precisely controllable metal deposition and forming of desired metal structure in produced 3D metal part.

xBeam Equipment

Read more

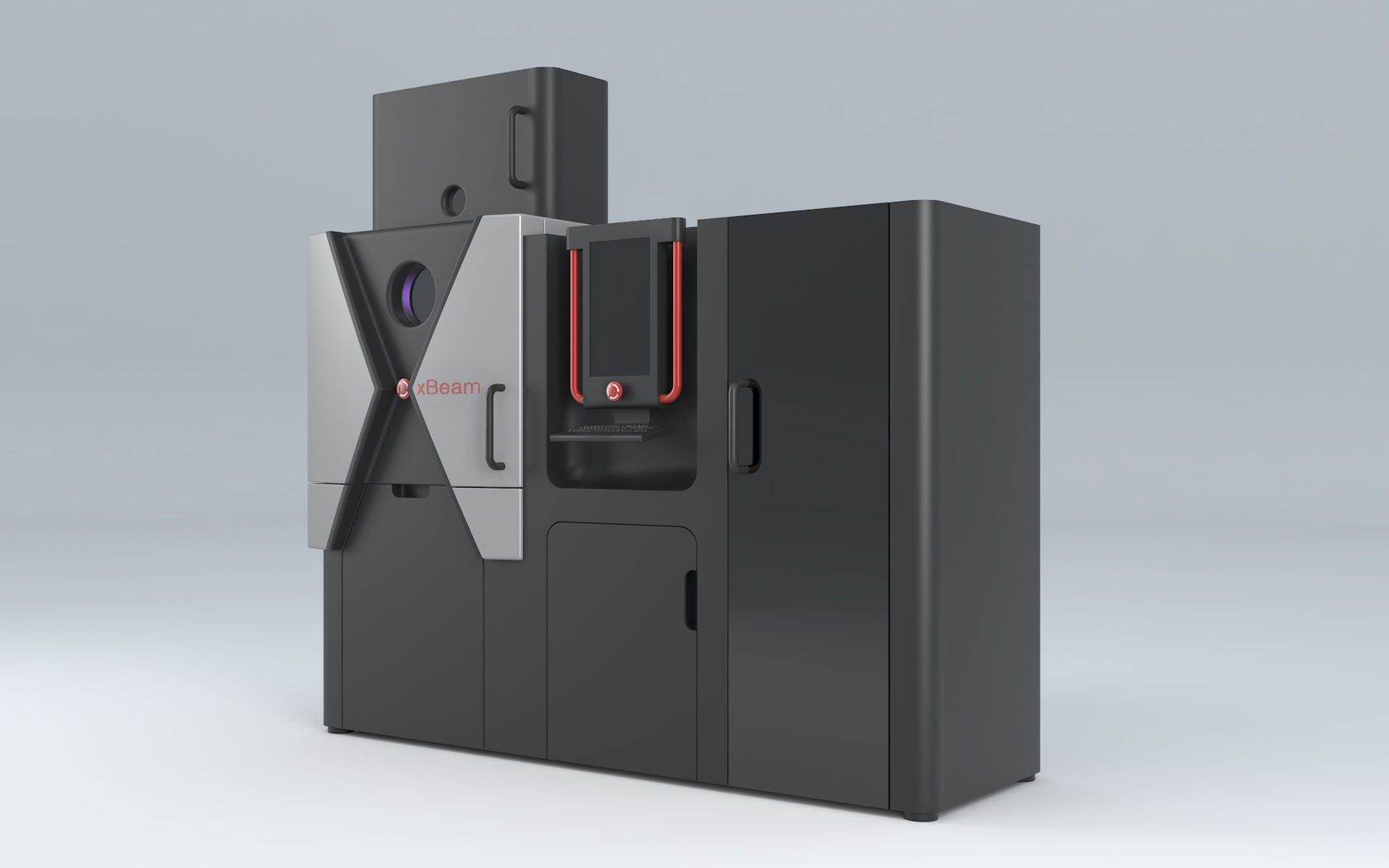

xBeamLab

Exclusive offer for AM market:

The only wire-based metal 3D printer for Research and Development that fits any laboratory room

The only wire-based metal 3D printer for Research and Development that fits any laboratory room

xBeamWorks

Exclusive offer for AM market:

Could be easily integrated into existing production environment, 3D-printed parts fit a medium size industrial CNC-machine

Could be easily integrated into existing production environment, 3D-printed parts fit a medium size industrial CNC-machine

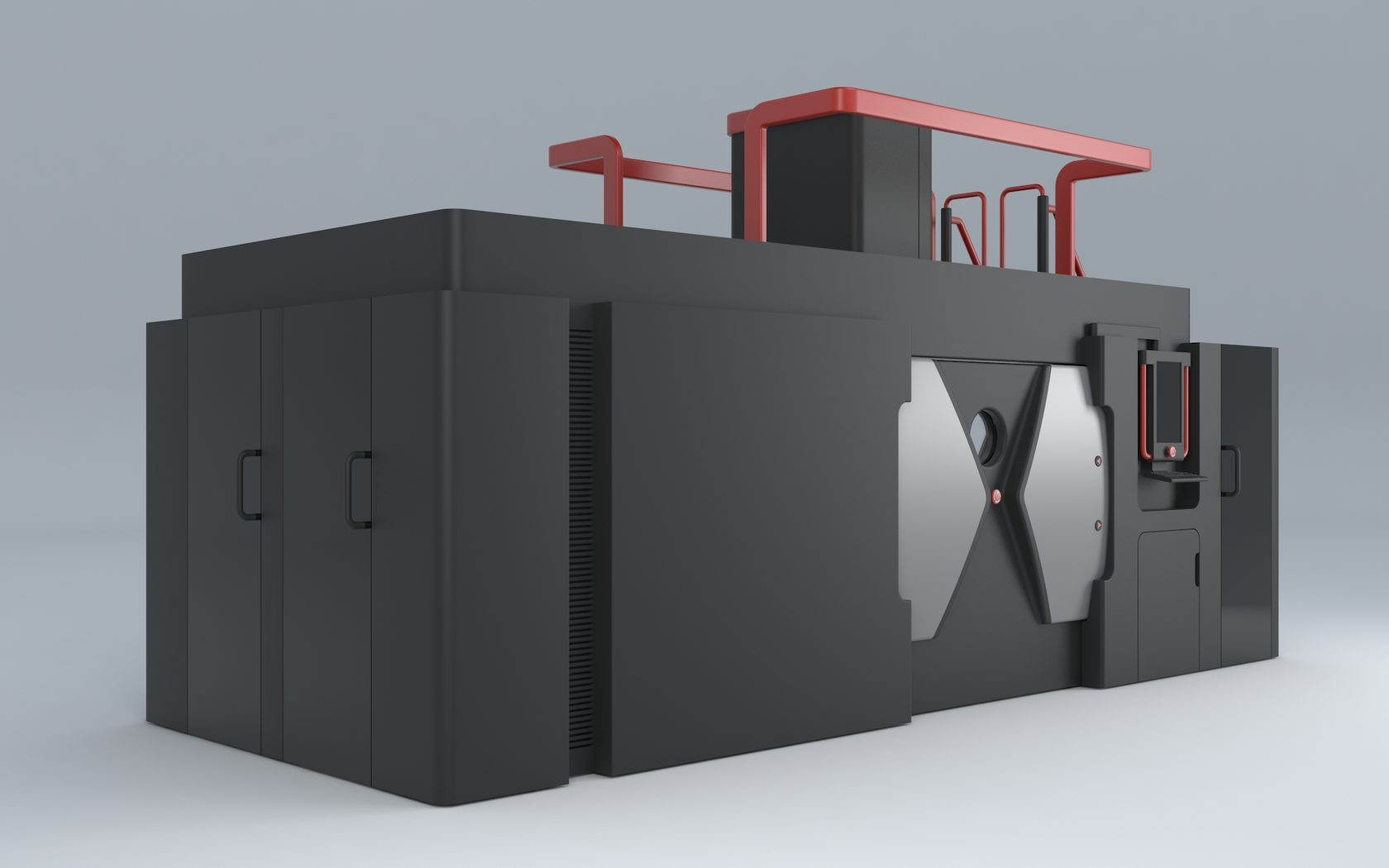

xBeamGrand

Exclusive offer for AM market:

Customized solutions for any request – any size, any configuration, increased power, increased productivity

Customized solutions for any request – any size, any configuration, increased power, increased productivity

Industries We Serve

About Us

Our exclusive xBeam 3D Metal Printing technology was invented as a result of more than 40-year experience of our scientists and engineers in development of electron beam technologies and equipment for wide range of applications. Our unique electron beam equipment is operating worldwide in industrial melting of ingots from titanium, niobium, tantalum and other metals, in different EB-PVD processes, for refining of silicon and noble metals to high purity level, for special welding and brazing applications as well.

Power range of our gas-discharge EB guns is from a few kW and up to 600 kW.

Providing high technological and operating capabilities of our electron beam equipment we were always thinking about customer's ideal requirements. We were always fighting with stereotype that electron beam technologies and equipment are complicated and expensive.

Finally we have broken this wrong statement concerning traditional EB technologies.

Now it is time to do the same in Additive Manufacturing making it close to scientific community and wide industry.

We know how to do it!

Probably only we know...

Read more

Power range of our gas-discharge EB guns is from a few kW and up to 600 kW.

Providing high technological and operating capabilities of our electron beam equipment we were always thinking about customer's ideal requirements. We were always fighting with stereotype that electron beam technologies and equipment are complicated and expensive.

Finally we have broken this wrong statement concerning traditional EB technologies.

Now it is time to do the same in Additive Manufacturing making it close to scientific community and wide industry.

We know how to do it!

Probably only we know...

Contacts

Please fill out the contact form below: